DESAN has taken the first official step for the second Multi-Purpose Mission Ship (MPMS 2), which will enter the inventory of the Malaysian Maritime Enforcement Agency (MMEA). With the steel-cutting ceremony held on February 11, 2026, at DESAN’s ATLAS Shipyard, the ship’s actual construction process officially began.

Set to Be One of the Largest Ships in the Malaysian Inventory

At 99 meters in length, MPMS 2 has been designed to have technical characteristics similar to MPMS 1, the first ship of the series. However, the second ship will be equipped with additional capabilities in line with current technological requirements. Targeted to be completed within 24 months, the vessel will, upon entering service together with MPMS 1, become one of the two largest platforms in the Malaysian Maritime Enforcement Agency’s inventory. Both ships are planned to be delivered by the end of 2027.

Operational Capabilities and Technical Equipment

MPMS 2, which will be certified by Türk Loydu, is set to create a force multiplier effect in coast guard operations with its wide mission spectrum and modern equipment. While the ship offers hybrid operational capability with four fast intervention boats and two Vertical Take-Off and Landing (VTOL) Unmanned Aerial Vehicles, its helicopter platform with an 11-ton capacity will also be able to support heavy transport and search-and-rescue helicopters. From a logistical perspective, the platform has a capacity to carry 70 personnel and 30 passengers and can conduct uninterrupted operations for 30 days without resupply. In addition, the fully equipped infirmary and medical services area on board, along with a detention capacity for 45 people, transform MPMS 2 into a versatile floating center for humanitarian assistance and law enforcement missions.

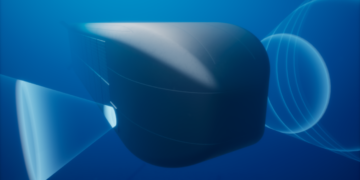

DESAN’s First Unmanned Surface Vehicle (USV) Export

The most strategic difference distinguishing the MPMS 2 project from its predecessor is the inclusion of one Unmanned/Autonomous Surface Vehicle (USV) developed by DESAN as part of the package. With this delivery, DESAN will realize its first USV export by carrying Turkey’s capabilities in this field to the Asia-Pacific market. Within the scope of the project, leading companies of the Turkish defense industry—primarily ASELSAN and HAVELSAN—are also undertaking the integration of critical components such as weapon systems, electronic warfare, and communications infrastructure.

Cenk İsmail Kaptanoğlu: “Permanent Cooperation in Southeast Asia”

Speaking at the ceremony, DESAN Shipyard Chairman of the Board Cenk İsmail Kaptanoğlu made the following remarks regarding the project:

“While the Hisar-Class Offshore Patrol Vessel and MPMS 1 projects are continuing at an intensive pace in our shipyards, today we have moved into the actual construction phase with MPMS 2. As the construction of three 100-meter military ships continues, we are once again demonstrating our competence on the global stage with advanced technology solutions such as USV integration. This project is the strongest indicator of our strategic partnership with Malaysia and our permanent presence in Southeast Asia.”

About the Steel-Cutting Ceremony

In maritime tradition, the steel-cutting ceremony is the most critical milestone, symbolizing the transition of a ship project from a design on paper to the physical production phase, marked by the cutting of the first steel plate that will form the ship’s hull.

Source: C4Defence – Desan