The Missile Defense Agency (MDA) has signed a new contract worth approximately $400 million with L3Harris Technologies for the solid rocket motors and control systems, which are critical components of the THAAD system.

L3Harris Technologies (NYSE: LHX) has achieved a significant supply milestone for the Terminal High Altitude Area Defense (THAAD) system, one of the cornerstones of the United States’ layered missile defense architecture. Through the system’s prime contractor, the company received a new work share valued at approximately $400 million to produce additional solid-fueled rocket booster motors and Liquid Divert and Attitude Control Systems (LDACS).

A Critical Component of THAAD: LDACS Technology

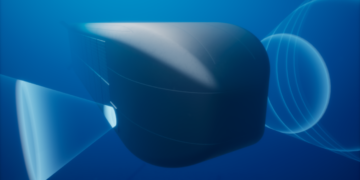

The THAAD system is the only system in the world capable of neutralizing short-, medium-, and intermediate-range ballistic missile threats both inside and outside the atmosphere. The LDACS system manufactured by L3Harris activates during the final phase of interception, keeping the “kinetic kill vehicle” precisely on target.

Ken Bedingfield, President of Missile Solutions at L3Harris, stated: “THAAD is a critical component of the U.S. missile defense system with its capability to intercept threats both outside and within the atmosphere. This system is vital to the security of our nation and our allies. We are committed to delivering our proven propulsion systems in the years ahead.”

100% Success Rate and Production Performance

Since entering production, the THAAD system has achieved a 100% success rate, successfully completing all 17 interception tests conducted to date. L3Harris demonstrated its production efficiency in 2024 by delivering its 1,000th solid rocket motor and 1,000th LDACS unit ahead of schedule.

Production and Operational Centers

L3Harris continues to develop the propulsion technologies considered the heart of the THAAD system at its strategic facilities across the United States. Production of the solid rocket booster motors is largely carried out at facilities in Huntsville, Alabama, and Camden, Arkansas, while the LDACS units—providing the system’s precise maneuvering capability—are manufactured at the company’s Los Angeles facilities. These highly responsive propulsion systems ensure interception success by keeping THAAD’s kinetic kill vehicle precisely on target during the most critical final phase of engagement.

Source: C4Defence / L3Harris Technologies